Polyvinyl chloride,

commonly abbreviated PVC, is a thermoplastic polymer. It is a vinyl

polymer constructed of repeating vinyl groups having one hydrogen

replaced by chloride. Polyvinyl chloride is the third most widely

produced plastic, after polyethylene and polypropylene. PVC is widely

used in construction because it is cheap, durable, and easy to assemble.

PVC production is expected to exceed 40 million tons by 2016. According

to IUPAC, polyvinyl chloride should be named poly (chloroethanediyl),

but the name is not used. |

|||||||||||||||||||||||||||||||||

It

can be made softer and more flexible by the addition of plasticizers,

the most widely used being phthalates. In this form, it is used in

clothing and upholstery, electrical cable insulation, inflatable

products and many other applications in which it would originally have

replaced rubber. |

|||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

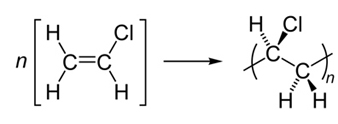

Polyvinyl chloride is produced by polymerization of the vinyl chloride monomer (VCM), as shown. |

|||||||||||||||||||||||||||||||||

The product of the

polymerization process is unmodified PVC. Before PVC can be made into

finished products, it almost always requires conversion into a compound

by the incorporation of additives such as heat stabilizers, UV

stabilizers, lubricants, plasticizers, processing aids, impact

modifiers, thermal modifiers, fillers, flame retardants, biocides,

blowing agents and smoke suppressors, and, optionally pigments. |

|||||||||||||||||||||||||||||||||

| The properties for PVC are usually categorized based on rigid and flexible PVCs. | |||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

While processing Plastogreen PVC

average content of PVC remains between 60 % - 70 % and balance portion

remains wood waste and additives. Plastogreen PVC is used for making water proof

MDF boards, Hollow doors, Frames, Filler boards. |

|||||||||||||||||||||||||||||||||